The EVAC ONLINE UNIT 300R is a high-capacity online vacuum generation and waste collection unit used primarily in vacuum toilet and sewage systems. It creates and maintains a vacuum to transport blackwater and graywater efficiently through a piping network without relying on large volumes of water.

Key Features

-

Vacuum Capacity: Around 300 m³/h (model-dependent) — suited for large systems.

-

Double-Stage Vacuum (DSV) Technology: Separates air and sewage phases, improving efficiency and reducing energy use.

-

No Need for Sealing Water: Saves fresh water compared to liquid-ring vacuum systems.

-

High Discharge Head: Can pump wastewater up to ~20 m vertically.

-

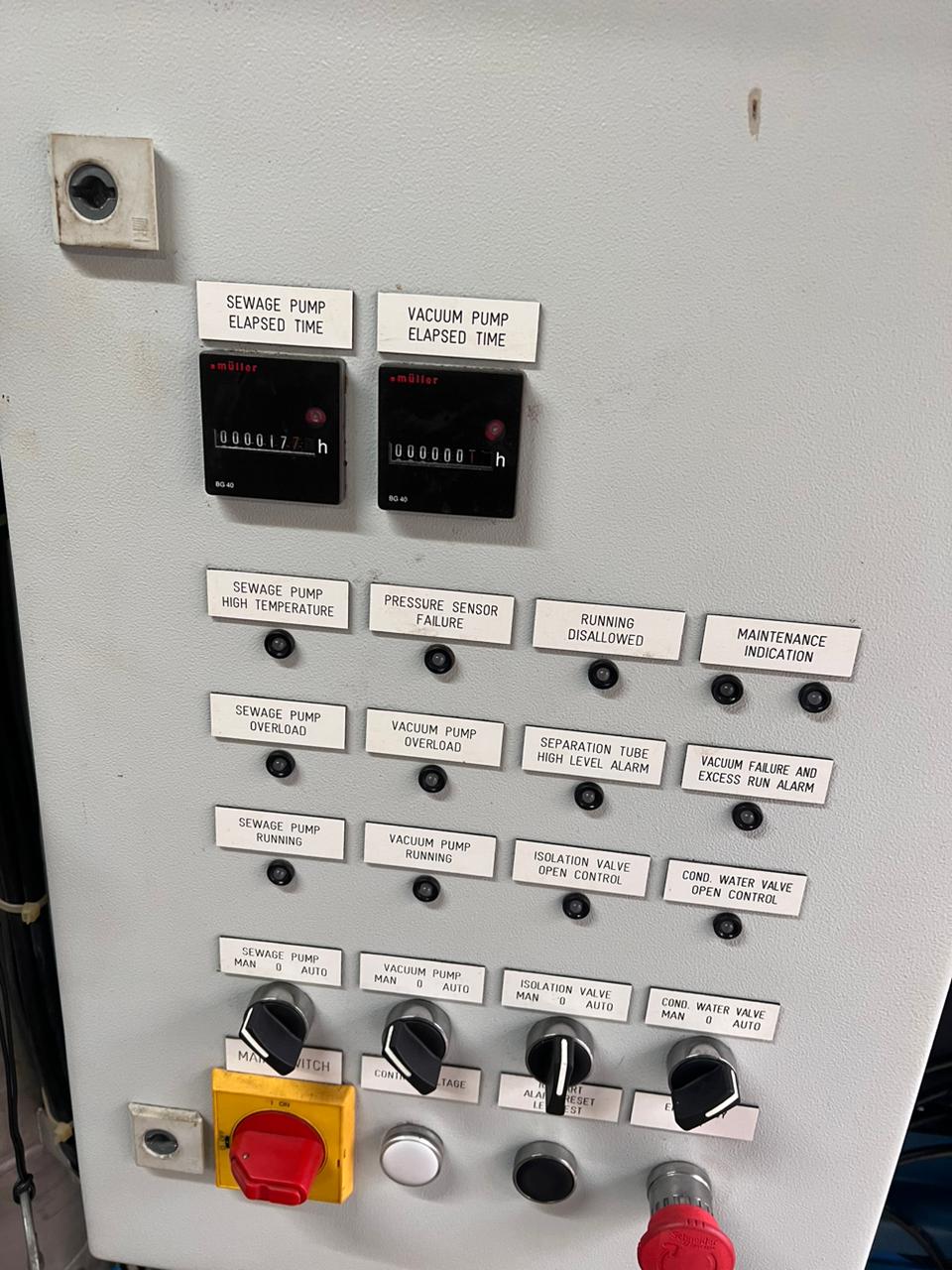

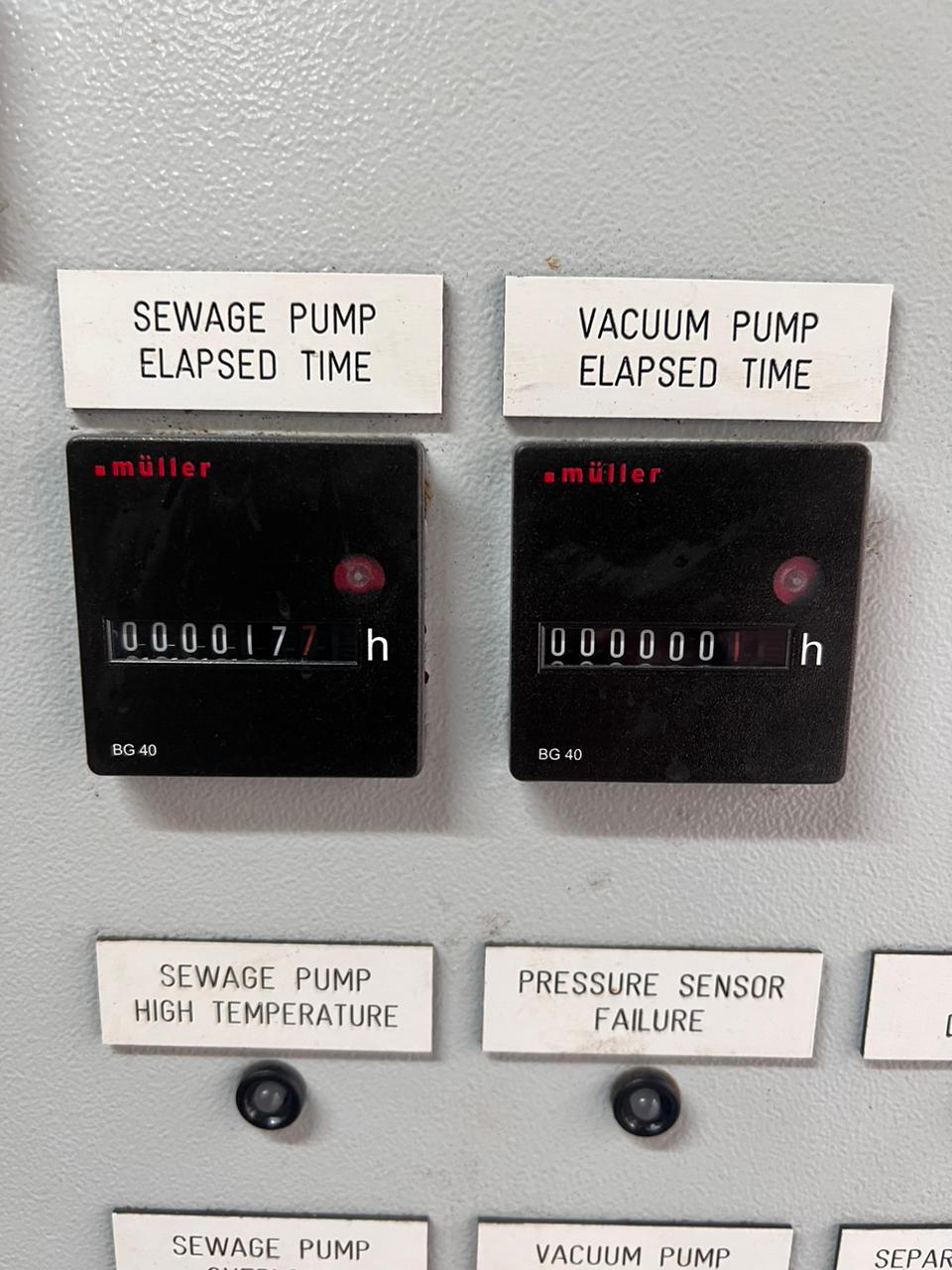

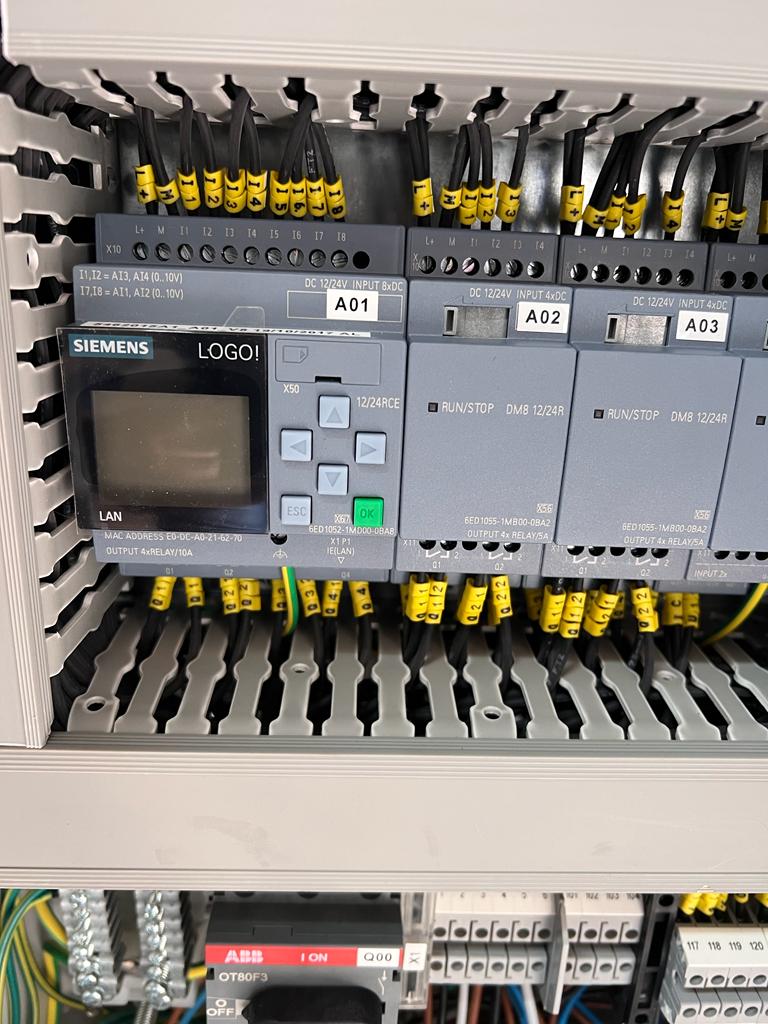

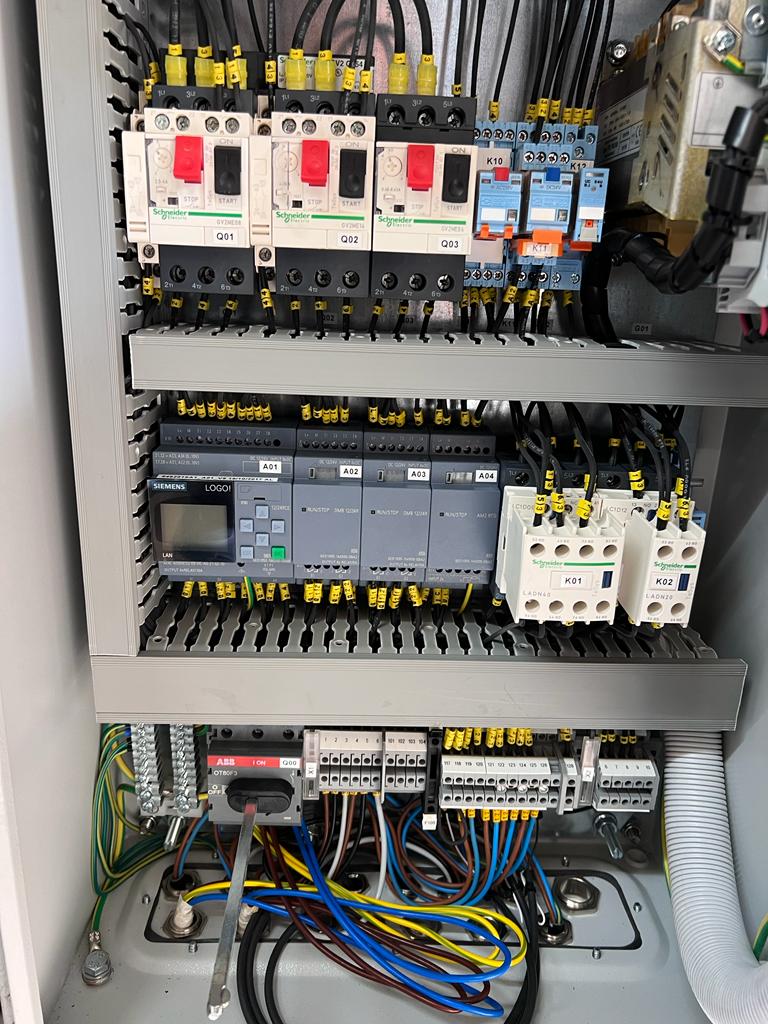

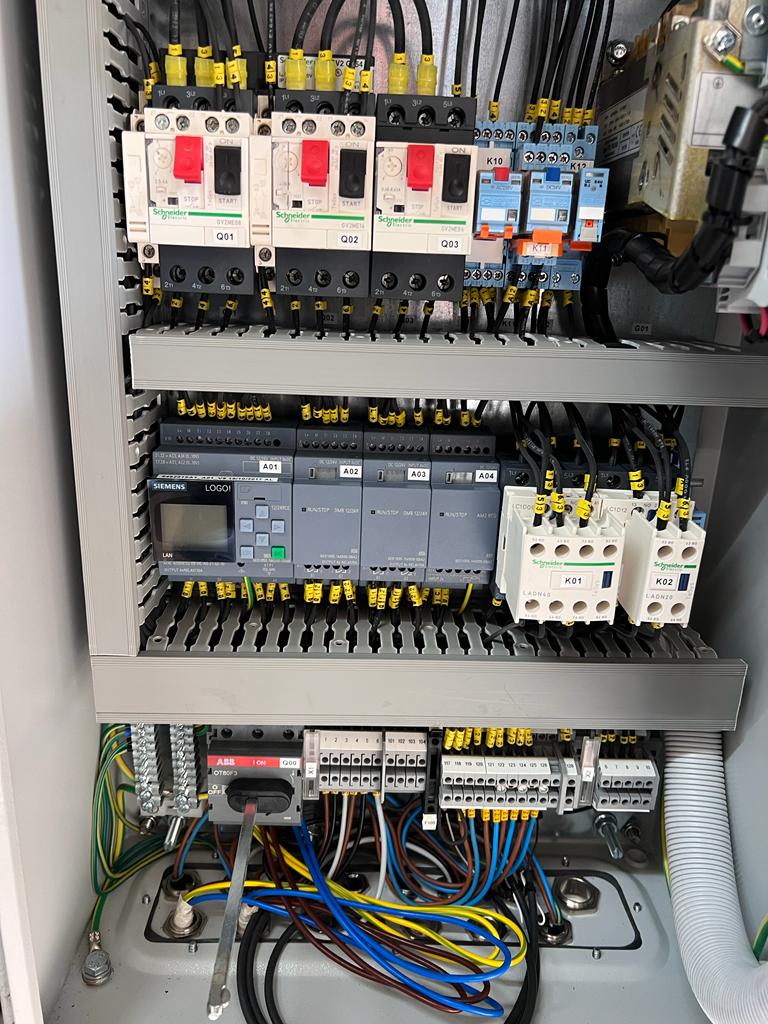

Automatic Operation: Controlled by sensors and PLC logic for continuous system vacuum and discharge.

-

Compact Footprint: Relatively small space requirement for the capacity delivered.

Marine Uses

1. Sewage Vacuum Systems

• Used onboard ships, cruise vessels, navy and commercial vessels to collect and move sewage and graywater from toilets and drains.

• Helps satisfy environmental regulations (such as IMO/MARPOL) by efficiently collecting waste before treatment or storage.

2. Integrated Marine Waste Management

• Often part of a larger marine system that includes vacuum collection, treatment plants, and wastewater handling.

• Energy-efficient and space-saving, making it suitable for large vessels with many toilets or high waste throughput.

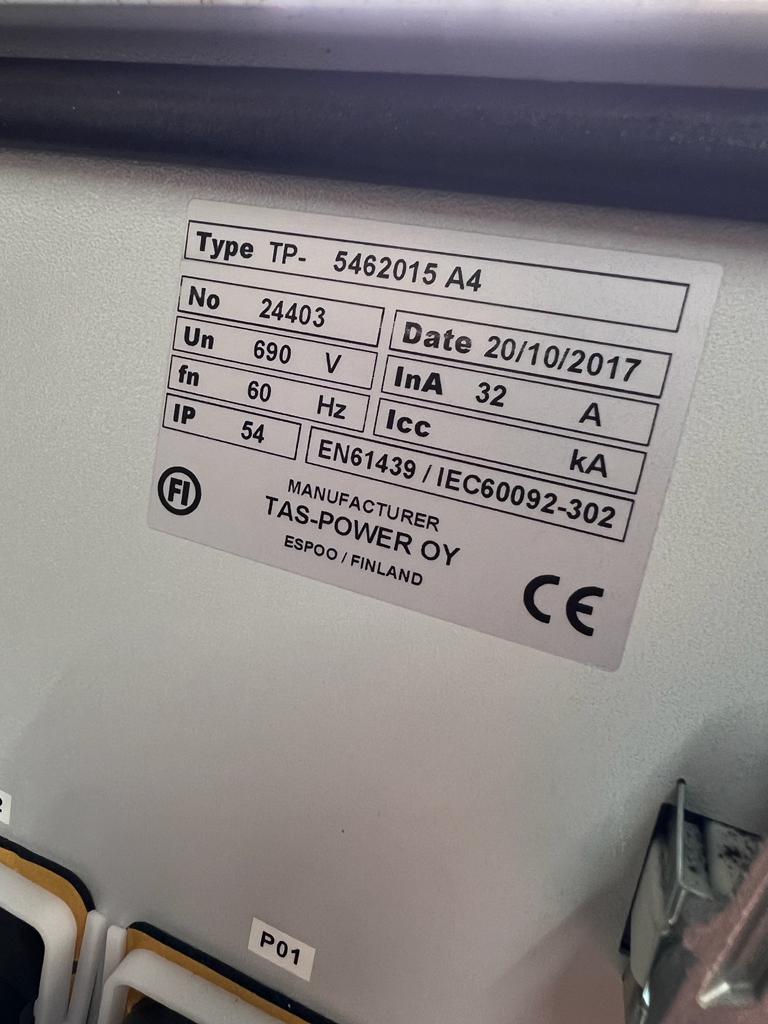

3. Retrofit and New Installations

• Can be added to existing systems as an upgrade or fitted into new ship designs due to its flexible installation options.

Industrial & Land-Based Uses

Although mainly known for marine applications, similar Evac OnlineMax R vacuum systems are used in industrial facilities where vacuum wastewater transport is needed:

1. Large-Scale Buildings

• Used in buildings with vacuum toilet systems (e.g., hotels, hospitals, campuses) to minimize water use and improve efficiency.

2. Wastewater Handling Plants

• In facilities requiring compact, efficient vacuum-based waste handling, particularly where gravity flow isn’t feasible.

How It Works (Operation Basics)

-

Vacuum Generation: The unit maintains negative pressure in the system.

-

Waste Collection: When a toilet is flushed or wastewater enters a vacuum line, the pressure differential moves it toward the vacuum unit.

-

Phase Separation: Air and waste are separated internally; air is released while sewage is pumped for treatment.

-

Automatic Control: A control PLC and sensors manage vacuum levels and discharge cycles.

Why It’s Used

✔ Energy Efficient — lower power use than traditional ejector/vacuum systems.

✔ Water Saving — no sealing water needed.

✔ Reliable & Automatic — minimal operator intervention.

✔ Flexible — works for new builds or retrofit projects.